6 Ways ERP Systems Change Manufacturing Operations in 2024

Sector: Digital Product

Author: Nisarg Mehta

Date Published: 05/14/2024

Contents

Managing supply chains, keeping inventory, and producing products on time and under the pen quality are some of the challenges manufacturing companies face. These problems may result in delays in production and a reduction in profits respectively.

ERP systems present a solution by combining pragmatic operations from different business sides into one unified effective system. This will in turn lead to the manufacturers simplifying processes, making better choices, and lowering their expenses.

ERP Fundamentals for Manufacturing Industry

ERP systems are built to perform as an integrated, automated mechanism of a manufacturing business. Basic manufacturing ERP systems usually consist of modules for inventory management, output scheduling, purchases, and logistics; the operations are coordinated so that they run together smoothly. This integration not only sends data to management teams but also ensures a seamless flow of information across departments that helps reduce manual data entry errors and also fosters customer trust by improving response times to market changes.

An ERP system can provide a complete view of production requirements to the manufacturers allowing them to control the production process and use the resources more efficiently. Such a holistic approach not only solves the management problem but also covers more strategic planning and tactics.

Benefits of Using ERP for Manufacturing Operations

Manufacturers can enjoy the following benefits of ERP systems:

1. Streamlined Operations

An ERP system will bring all your manufacturing processes into one software environment. Hence, activities like order processing, production management, and shipping are carried out in a way such that these tasks are interlinked thereby shortening the time and effort that was usually invested in manual coordination. ERP systems take the role of getting rid of the typical low-level tasks improving the accuracy of the work while allowing employees to be more creative and work on the value-added activities.

2. Enhanced Decision-Making

In ERP systems, managers get real-time information from all departments, from which they make decisions in a matter of time. Whether it is adapting production schedules based on new orders or redirecting resources because of supply chain disruptions, having at hand real-time information allows leaders to make effective decisions that are based on the current situation and not old reports.

3. Cost Reduction and Efficiency Optimization

Besides saving resources and money spent on some activities by means of increasing process efficiencies, ERP systems allow for achieving cost reductions. They help reduce stock requirements, improve buying practices, and facilitate the use of production resources. These systems, in turn, can find the production bottlenecks and make the appropriate substitutions that may save time and money.

4. Improved Quality Control

The absolute importance of quality control cannot be understated and this is what the ERP systems are known for with the features that track the product quality from the raw materials to the finished goods. Automated quality tests and tracking systems, enabled by ERP, eliminate the risk of defects enabling manufacturing of only those products that fulfill first-class quality standards and are supplied to the customers.

5. Compliance and Risk Management

ERP systems enable the manufacturer’s compliance with industry regulations by establishing unified procedures and keeping detailed records to ensure conformity. This aspect is very important in industries that are highly governed like pharmaceuticals or food and beverage. Besides, being able to prevent a disaster before it can call for full attention is an important feature of ERP systems.

6. Scalability and Flexibility

With an increase in businesses, the processes and procedures become even more complex. Notwithstanding the increased functionality and growing numbers of employees involved in the process, ERP systems can be scaled up to cope with new business processes and more. Thus, it is much more comfortable for firms to start scaling manufacturing operations and implementing different marketing strategies to fit in new or changed markets without harming the business as a whole.

Challenges in ERP Implementation in Manufacturing

It is no secret that while introducing an ERP system in a manufacturing environment usually has its benefits, it may not be that easy. Among the biggest obstacles is data migration which involves a lot of complexity. The transformation of data from existing systems into a new ERP system usually demands lots of time and energy for picking up the data errors from the old system and their matching to the new one.

The next challenge is change management. Employees whose bread and butter were these old systems may hesitate in changing to a new ERP system having to undergo an exhaustive training process as the transition progresses.

These challenges could be effectively addressed by the involvement of the stakeholders across the process. Additionally, companies should communicate the benefits of the implementation of an ERP system and how it will add to their efficiency and the company’s effectiveness.

The soft launch with limited functionality can be very rewarding to give the people time to experience and adjust to the new system before implementing full functionalities. Stepwise approach as a way to reduce disruptions and pinpoint troubleshooting issues in the most manageable sections.

Lastly, when it comes to migration, partnering with an experienced ERP development and integration company like Techtic can help you in this regard. We can onboard the next ERP system into your existing technology infrastructure without any disruption.

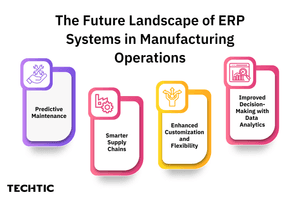

Future of ERP in Manufacturing

Emerging technologies like artificial intelligence (AI), the Internet of Things (IoT), and machine learning are baking the future of ERP systems in manufacturing. These technologies are enhancing ERP functionalities in several ways:

1. Predictive Maintenance

The IoT in ERP systems makes it possible to check out the equipment’s condition in real-time. Sensors can monitor the status and identify the failure of a machine before it breaks down, thereby the maintenance engineer can do the reactive maintenance before the machine breaks down so as to lower the downtime; thus the machine life gets increased.

2. Smarter Supply Chains

AI provides the ability for big data management and therefore improves supply chain management. It is an aspect of supply-chain management that includes demand forecasting, inventory level management, and logistics planning that will eventually have a positive impact on the profit margins and service experience.

3. Enhanced Customization and Flexibility

As companies embark on an effort to sell out a defined customer requirement more and more ERP systems are being designed to be customizable. However, this adjustability gives companies the advantage to tailor products just so and also respond swiftly to market shifts.

4 Improved Decision-Making with Data Analytics

With the help of innovative analytics functions, ERP systems of today are able to turn the raw data into actionable business intelligence. This allows manufacturers to discover the blind spots, introduce profitable innovations, and make more informed decisions on the overall strategy of the enterprise.

These technological integrations not only serve to make operations more efficient but manufacturers also are given the opportunity to foresee changes and to adapt readily, thereby, remaining on top of a competitive environment.

ERP is the Way Forward to Efficiency and Scale for Manufacturers

Through the automation of operations, ERP systems are fundamentally transforming the manufacturing landscape. Advanced ERP systems provide an added advantage to the sector in decision-making and cost efficiencies. These systems not only integrate different aspects of manufacturing operations but also enable easy management of complex processes and quick response to changing needs.

The implementation of an ERP system may be difficult, but the ultimate benefits—in the form of efficiency, cost reduction, and quality improvement-are more significant than any challenges. With technological evolution, ERP systems would continue developing and resulting in greater capabilities and integration.

Nowadays, for those manufacturers that want to be one step ahead and be as flexible as the market conditions demand, opting for an ERP system must not only be beneficial, but compulsory as well.